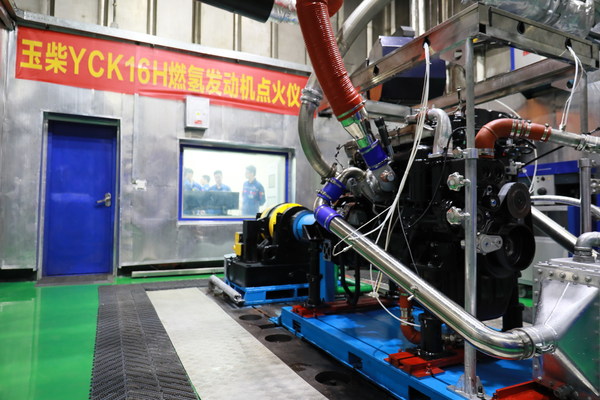

YULIN, China, July 1, 2022 /PRNewswire/ — On June 30, Yuchai YCK16H hydrogen-fueled engine was successfully ignited in Yulin, Guangxi. The engine, with a displacement of 15.93 liters and a maximum horsepower of 560 hp, is the largest hydrogen-fueled engine with the largest displacement and horsepower in China. The successful ignition of Yuchai YCK16H marks another solid step forward for Yuchai in the zero-carbon energy power system segment.

Li Hanyang, Secretary of the Party Committee and Chairman of Yuchai Group, ignited YCK16H. He said that the new energy engine field has developed rapidly in recent years. Yuchai, as a manufacturer of traditional engines, has taken the initiative to embrace clean-energy engines, made breakthroughs in clean-energy engines, and supported China’s strategic goals of “carbon peaking and carbon neutrality” with Yuchai’s responsibility and commitment.

Heavy-duty hydrogen-fueled engine YCK16H ignited successfully

Yuchai leading the zero-carbon energy power system segment

In December 2021, Yuchai successfully ignited China’s first hydrogen-fueled engine YCK05H oriented to urban buses, municipal administration, sanitation, logistics and distribution fields, driving China’s internal combustion engine industry into the zero-carbon energy power system segment, and marking the start of the R&D of hydrogen-fueled engines for commercial vehicles in China.

After completing the development of the light-duty hydrogen-fueled engine platform, Yuchai has launched YCK16H heavy-duty in-cylinder direct injection hydrogen-fueled engines, making Yuchai the only professional power system supplier covering light-duty and heavy-duty hydrogen-fueled internal combustion engines and fuel cell systems in the field of hydrogen energy in China.

The ignited YCK16H adopts advanced fuel high-pressure common rail, high-pressure in-cylinder direct injection technology and dual-channel turbocharging technology, which can realize homogeneous combustion or stratified combustion in the cylinder as required, featuring stronger power performance, higher thermal efficiency and better stability. The platform has high adaptability to fuel purity and can be adapted to fuels prepared by grey hydrogen, green hydrogen, methanol-produced hydrogen, and other means. The fuel supply can be freely combined according to user needs and the basic conditions of fuel production, storage and transportation, which is a highly adaptable, flexible and controllable zero-carbon/low-carbon power solution. To solve the problem of the relatively small power per liter of hydrogen-fueled engines, Yuchai chose the YC16H platform, which has higher horsepower but is smaller and lighter than similar products, and can be widely used in scenarios such as 49T tractors and other heavy commercial vehicles and distributed energy sources.

Stronger reliability and adaptability

Laying the technical foundation for zero-carbon emission internal combustion engines

Unlike other product platforms, the application of various alternative fuels puts forward higher requirements on engine reliability and adaptability. YCK16H adopts the independently developed intelligent control system and high-efficiency air management system, which can realize both equivalent ratio combustion and lean combustion, and can adjust the injection fuel pressure and air intake volume according to different fuels, so as to give play to the role of different fuels efficiently. It applies high-reliability fuel injection system technology, electric-driven closed recirculation technology and advanced exhaust gas recirculation technology to prevent the occurrence of problems such as difficult ignition and unstable combustion in ammonia-fueled internal combustion engines. It adopts intelligent variable control technology, which can convert different fuels by adjusting the fuel system and intelligent control software without changing the main body of the engine, so as to reduce the development cost of vehicle manufacturers and better meet customer needs.

The application of ammonia fuel and methanol is also one of the highlights of this engine platform. Compared with hydrogen, ammonia fuel and methanol feature lower preparation cost, easier storage, wide application and less environmental impact. Based on the above advantages, ammonia-fueled internal combustion engines and methanol-fueled internal combustion engines have a broader development prospect. The development of YCK16H provides a good technical platform for the application of single fuel of ammonia or methanol, ammonia-hydrogen blended fuel and diesel-methanol blended fuel, and lays a technical foundation for China to develop zero-carbon emission internal combustion engines.

It’s said that the natural gas engine YCK15N developed based on this platform has completed bench tests and vehicle road tests, and is expected to be put into mass production by the end of 2022. The verification results show that YCK15N has higher reliability, the number of cylinder head low-cycle fatigue cycles increases by 2.35 times, and B10 reaches 1 million kilometers. It adopts the industry’s first EGR system and crankcase system anti-icing patented technology, and can still operate normally at -40℃. It is cost-effective for it has adopted the industry’s first TWC (three-way catalyst) + ASC(ammonia slip catalyst) + decarbonization technology, which means that the endurance mileage of this product doubles, the lowest gas consumption is at least 5% lower than that of similar products, and the torque is larger than that of similar products. This product will be widely used in 6X4 high-end tractors for trunk line logistics, and standard-load composite tractors in mountainous or plateau areas.