Instead of averting hidden carbon footprints in the EV ecosystem, they focus only on improving market competitiveness.

Despite mounting scrutiny of electric vehicle (EV) manufacturers’ hidden environmental impacts, most automotive companies have been more focused on reducing costs and improving EV car range rather than improving the vehicles’ carbon footprint.

According to independent research into EV development, while such vehicles do not produce tailpipe emissions, their manufacture—including that of the single-use batteries inside them—harbors increased demand for fossil-fuel generated electricity and relies on energy-intensive materials and processes.

Other reports mirror this hidden impact, finding that EVs are far “dirtier”: they have to clock up nearly twice as many miles compared to petrol cars to make up for the carbon-intensive electric drive trains.

Roadblocks to EVs’ green promise

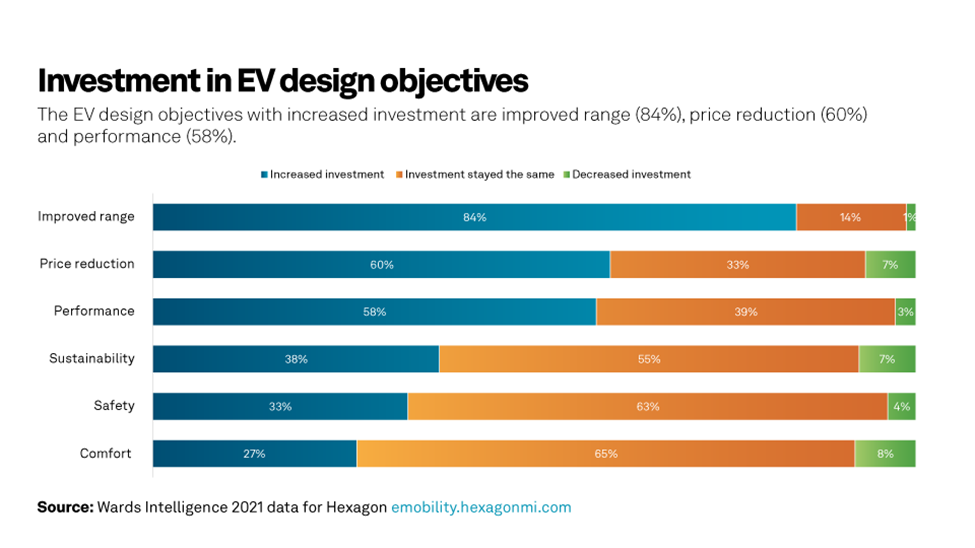

Despite this challenge, only 38% of EV makers researched were currently increasing their investment in more sustainable EV designs, which appears to be a much lower priority than environment conscious buyers are aware of.

The research also found that EV makers studied were focused on increasing:

- investment in improving EV range: 84%

- investment in design that will enable lower production and retail costs: 60%

- investment in improving EV performance: 58%

These factors all improve the environmental footprint of an EV compared to a petrol- or diesel- based vehicle, but achieving the full ‘green promise’ is being hit by roadblocks. When asked to describe their challenges in achieving greener EVs, 56% of EV makers surveyed (56%) indicated.

- a lack of alternatives to rare-earth metals for batteries

- concern over the lack of recyclable battery materials: 49%

- the lack of recycling programs and infrastructure (47%)

- supply chain vulnerabilities (exemplified by the ongoing global chip shortages) in sourcing the required volumes of materials: 73%

The research by Hexagon draws from original work conducted with Informa Tech Automotive Group’s research division, involving a survey of 416 eMobility design and manufacturing decision-makers across the global automotive supply chain.

According to Ignazio Dentici, VP Global eMobility Industry, Manufacturing Intelligence division, Hexagon, the EV industry recognizes that sustainability involves more than merely reducing road emissions. This reveals “an understanding of the whole-lifecycle manufacturing and material impact of vehicles. However, it also shows that despite this knowledge, EV makers are feeling more pressure to compete for consumer sales than to ensure EVs are able to fulfil their core purpose of reducing the environmental impact of road transport.”

The way forward

EV makers should address different ways of smart manufacturing, including vertical integration of production and open digital ecosystems that enable end-to-end visibility and control over materials across their life cycle.

“To fulfil the promise of a net zero automotive industry sooner while balancing consumer demands, intelligent data-driven manufacturing approaches must be embraced that support the development of sustainable solutions for every part, as well as creating recyclable cars. Only by designing for a circular economy—from factory, to consumer and beyond—can we reduce demand for energy and materials in the coming years,” Dentici urged.

Adopters of smarter product development and manufacturing approaches have reported cutting time-to-market by 25%, with the methods producing lighter, more recyclable materials, and more autonomous manufacturing, leading to progressive reductions in development timelines and costs.

Furthermore, synchronizing design, testing and engineering has been shown to dramatically reduce physical testing and failed products, providing engineers with the opportunity to address efficiency and sustainability at the drawing board stage.