With electric vehicles set to become common, one parts maker is turning to MBD to grab a share of the pie.

In the automotive components manufacturing industry, one of the paths of digitalization involves model-based development (MBD).

By using MBD, manufacturers can resolve existing issues as well as investigate a broad range of design possibilities, early in the process and before physical models are built. Model-based development is expected to reduce time needed for product development, cut costs, increase design quality, and improve competitiveness.

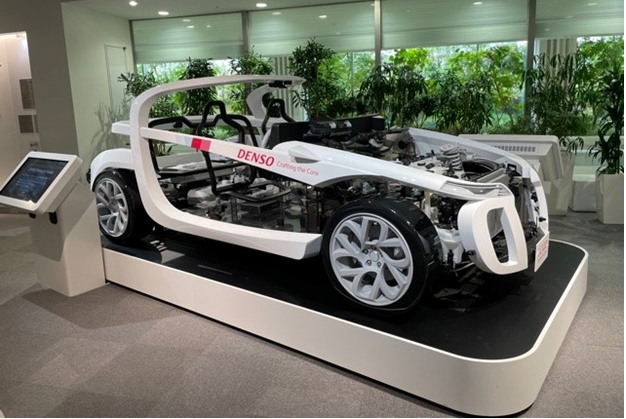

That is what one firm, DENSO, is doing in response to what it claims is a “once-in-a-century transformation”. The firm’s long-term effort to pursue value from both the vehicle and subsystem perspectives is a strategy to enhance growth and profitability, according to its General Manager (MBD Promotion Dept), Masaki Suzuoki.

Large-scale MBD deployment

DENSO has earmarked electric vehicles and the implementation of advanced safety and automated driving as paths to achieving greater business value. To achieve these goals, the firm has begun the roll-out of MBD across the entire company, supported by its research in Europe where direct discussions with established MBD solution providers.

One such European MDB innovator had been DENSO’s long-term partner for other developments. By tapping on the synergy, DENSO’s selected Siemens Digital Industries for its MBD project. The two firms have been working together to develop solutions based on their aligned strategies, with DENSO submitting requests to Siemens for MBD that are implemented as standard functions of the latter firm’s solutions.

DENSO is currently conducting a trial roll-out through a cross section of various fields, including their primary domains of thermal systems, powertrains, and electrification. Implementation of these standard functions benefits not only DENSO, but all companies implementing MBD, including those within the automotive industry.

Suzuoki noted that the partnership on a three-year MBD pilot has been successful: “Full scale deployment will start throughout the company in Japan and abroad and we look forward to additional support from Siemens that can help us accelerate MBD deployment across business domains.”

Benefits of MBD in modeling work

The partnership includes the provision of a variety of services including process consulting, conducting pilot projects at design sites, and establishing processes for modeling.

Through the use of a proprietary portfolio of simulation and test applications, DENSO can continue to drive implementation of system simulation in the development process. Siemen’s solutions are being deployed for use by designers who can now conduct one-dimensional system simulation alongside analysis specialists, while other advanced MBD software tools can be used to enable seamless distribution of model data among global sites.

Siemens Digital Industries’ President and CEO, Tony Hemmelgarn, said: “We appreciate the trust of DENSO and the other global automotive companies that have chosen (our) software and services for digital transformation, as well as effective and profitable operations.”