Small-scale low-cost bespoke merchandise manufacturing may someday be viable due to digitalized ICS, but data protection and security issues need addressing.

Do you know what a ‘customized future’ refers to? As part of Industry 4.0, a ‘customized future’ points to a future where many products and services are made based to suit specific customer preferences.

Also known as ‘personalization’—a trend introduced by 4G mobile ultra-broadband—it refers to the empowerment of consumers to grab a cab when they need one, or stream the song or content they want to—all at the touch of a few commands, and with customized deals and rewards pushed to their attention regularly.

With more advanced technologies rising, many consumers (to the tune of 83%, according to some studies) value personalized experience so much that they are willing to divulge their personal data to make it possible. In fact, consumers are unknowingly giving more data than they have bargained for.

For instance, what seems like a simple song choice when made multiple times and then analyzed, can allow music streaming companies to predict a user’s mood at a certain time and location. The same goes with dating apps that can tell if one is in a sad and vulnerable state, and at which time of the day, based on the number of customer’s swipes from left to right.

Then there is the controversial topic of location tracking, which allows apps to amass a huge amount of data that allows businesses to predict their behavioral and physical patterns. All the bits of preferences, habits and tracked behavior can be used to piece a digital twin of a person to predict how that person may react to various stimuli.

It is therefore clear that such data can be a big risk when held or abused.

APAC ICS threats

Several start-ups across the world, aware of the demand for customization and personalized manufacturing, have since kicked off their mass customization practices. Consumers can now have their own names on the sole of their shoes, get a bespoke necklace made to personal taste, or order tailored body implants, personalized medicines, and more.

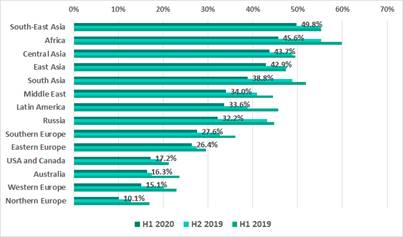

While these are proofs of the power of technology when harnessed correctly, the flexible and digitalized manufacturing process—Industrial Control Systems or ICS—also opens a wider attack surface for cybercriminals. According to one report from Kaspersky during H1 2020, Asia and Africa had the least-secure ICS globally during the first six months of 2020. The Asian regions occupied four out of the top five positions in the regional rankings based on the percentage of Industrial Control Systems (ICS) computers which were almost infected in the first half of the year.

South-east Asia recorded the highest percentages, leading in several ratings:

- percentage of ICS computers where malicious activity was blocked: 49.8%

- percentage of ICS computers where internet threats were blocked: 14.9%

- percentage of ICS computers where malicious email attachments were blocked: 5.8%

Africa came in second while Central, East, and South Asia follow closely at third, fourth, and fifth places respectively.

In terms of ransomware, regions in Asia still led with a noticeable margin in the regional rating. Over half of the countries in the top 15 ranking were from APAC.

Securing ICS for safe personalization

According to Stephan Neumeier, Managing Director (Asia Pacific), Kaspersky: “It is not surprising that ICS computers in the Asia Pacific were exposed to the highest number of cyber threats, as the region is well on its way in building a customer-centric future. Smart systems and automated productions require in-depth, intelligent defenses to foil malicious disruptions, with possible aftermaths that can cross from the virtual to the physical realm. To avoid grave circumstances, a secure-by-design approach is necessary. Cyber-immunity against attacks should be ingrained at the very fabric of the present and the future industrial systems.”

One example of a securing digital transformation that hinges on personalization is the first smart floating fish farm of Singapore Aquaculture Technologies. The innovative farm employs technology to address the declining of fish populations caused by climate change, and produces 350 tons of fish annually to cater to market needs for quality fish.

According to Raimund Klein, Executive Vice President (Southeast Asia), Siemens Digital Industries, which was instrumental in the farm’s technological infrastructure: “Consumers now are concerned about the origin of their food, the type of environment it is from, and the harvesting processes done before it arrives at their dinner table. With climate change and environmental challenges, food production should now be both ethical and sustainable. This is possible when we use available technologies right.”

Klein said that, by using innovative advanced predictive tools such as machine learning and video analytics, his firm enabled the fish farm to preempt potential biomass growth and prevent the outbreak of diseases, hence reducing fish mortality. “We are also paving the way for scalable, highly-flexible and above all, environmentally-efficient aquaculture across the entire value chain,” he added.